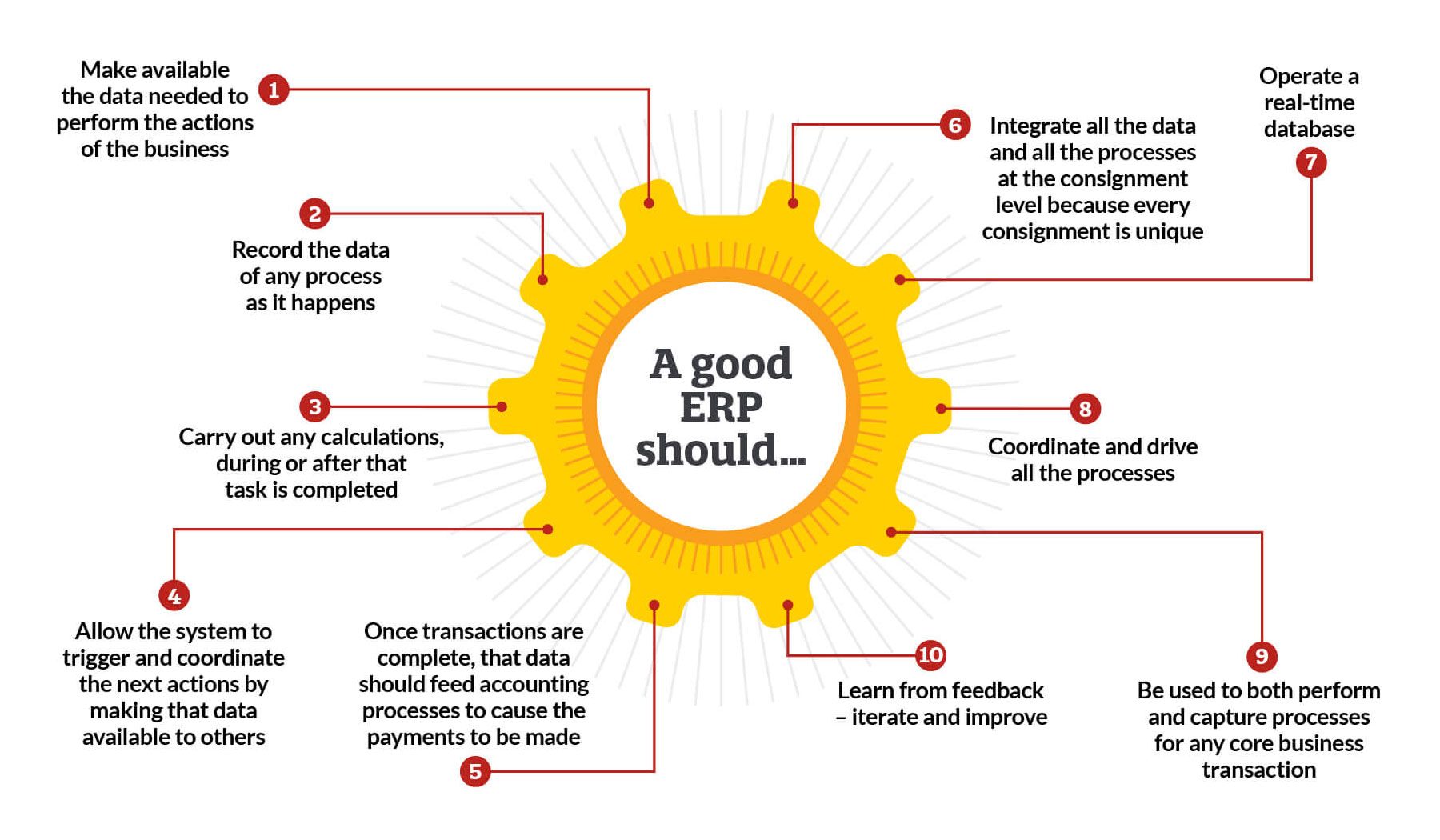

Businesses are about processing transactions – for fresh produce – orders for fruits and vegetables and the services associated with handling those goods.

The normal core process functions covered by a fresh produce ERP are:

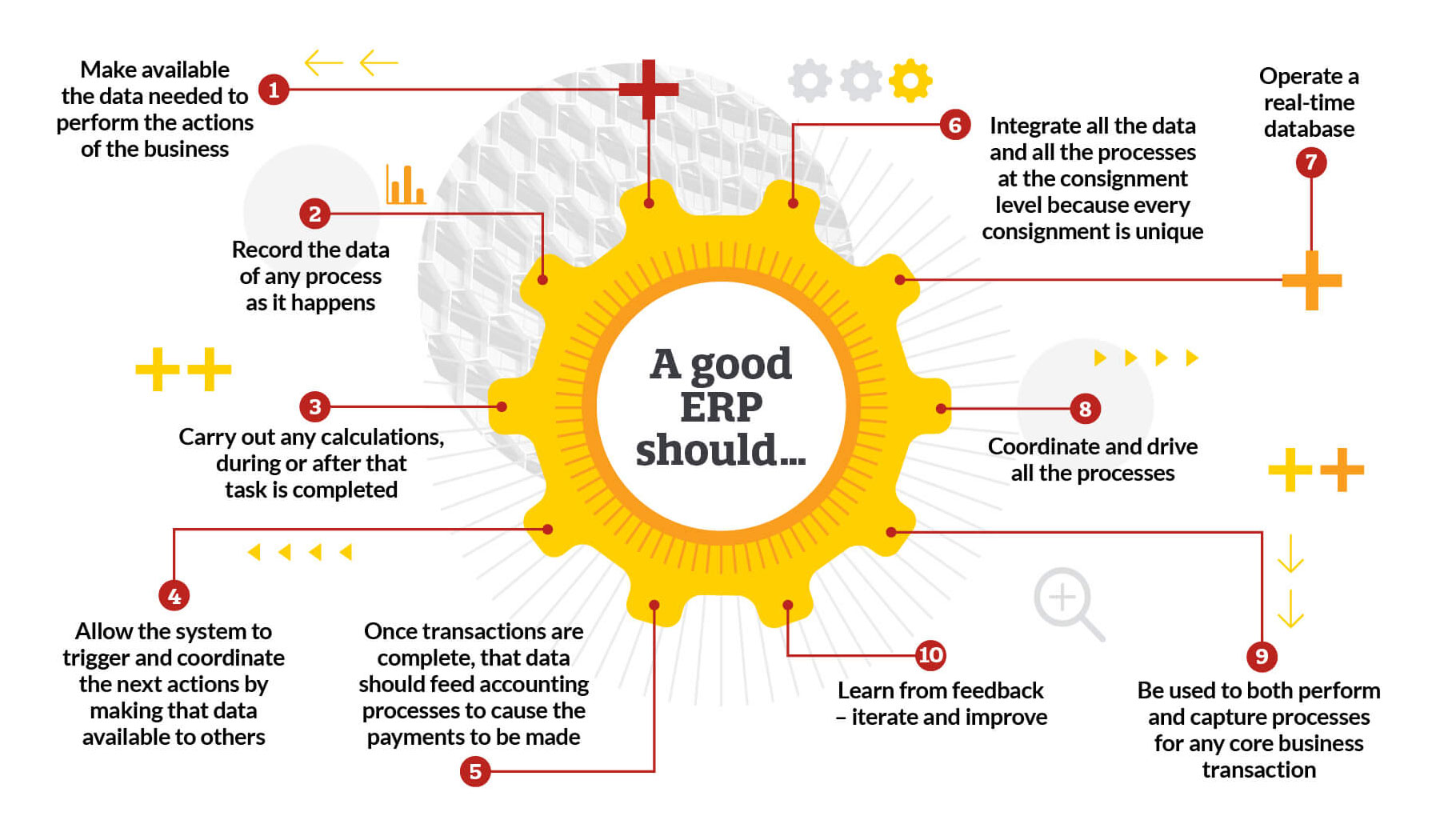

No software will provide a great solution for the fresh produce business without decades of dedication to understanding the specific and shifting needs of fresh produce.

Strong ongoing collaboration between the ERP software provider and the fresh produce organisation is needed in order to iterate the design, improve the business processes, and to incrementally solve more problems and deliver enhanced benefits.

The integration of these systems have been known to overrun by many years and only include basic functionality. The business will still need to maintain spreadsheets or external poorly-integrated stand-alone software.

General ledger mechanisms focus on average cost of stock, and possess poor information systems for the fresh produce environment. They often fail to deliver customer and product profitability.

Sometimes companies fail with their attempts to move from older “green screen” systems which use basic computer technology. These companies struggle on, hindered by an ERP that lacks the sophistication and processing power to cope with the complexities of the fresh produce supply chain.

These do not have a core file structure, i.e. consignment-based, and they do not focus on activity-based costing and accurate, rapid consignment, and sales order profitability.