In 2011, technology analysts at Forrester Research made a similar observation for automation requirements within large service organisations. They argued that high-volume repeat tasks like payroll, accounting, finance, order management and human resources have largely been automated. But there remains a long tail where task patterns become less frequent. This aspect of business delivery requires extensive manual work and temporary staffing to address bursts of activity. Forrester Research suggested that 50% of all automation opportunities are being missed.

The long tail opportunity for the fresh produce industry is to successfully embed data exchange and smart software across the supply chain, thereby allowing people to focus on value-add tasks and innovation, rather than their time being consumed by bureaucratic tasks.

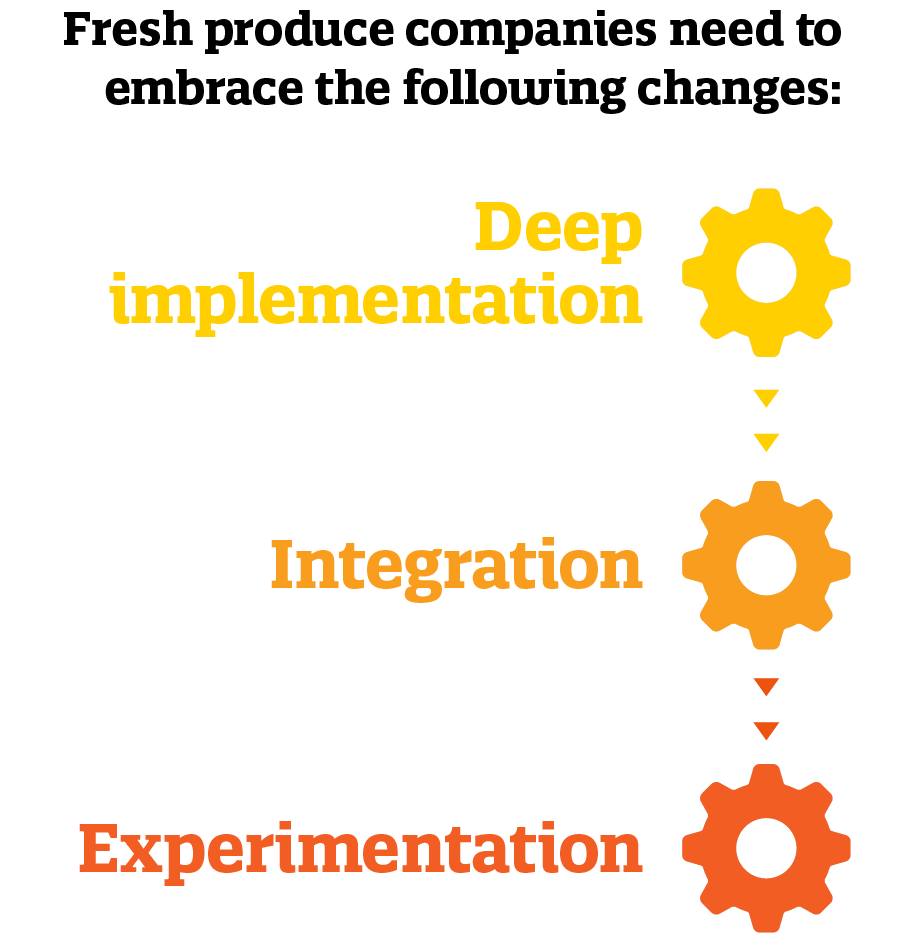

Companies are most likely to embrace new opportunities where a material gain can be achieved without the need for wholesale reinvestment by all supply chain players at once. Business systems have to be capable of evolution, otherwise people will return to standalone spreadsheets or manual processes.

Lessons of the past show that productivity gain is delivered through a strong understanding of the fundamentals of the fresh produce supply chain; there is a need to have a holistic approach, a need to invest in people and skills, and an investment in robust data infrastructure and smart software.

The execution of the fresh produce supply chain has so many sources of uncertainty and change. This uncertainty is the “noise” that can prevent businesses from taking a comprehensive holistic approach to understand the fresh produce ecosystem, evaluate and solve problems, and meet the expectations of customers.

The need for a broad understanding of the provenance of fresh produce encourages the exchange of more data about the growing, harvesting and condition of the product as it flows through the chain – improving the prediction of what the product will be like at each stage and what to expect from handling and settlement. This will ensure less disappointment and a reduction in the waste experienced – as products are not sent to the wrong place or at the wrong time.

The delivery of incremental supply chain improvements requires an investment in the data and digital skills of a workforce; digital literacy needs to be embedded throughout an organisation.

A recent WRAP report stated: “The delivery of the potential benefits from these technologies is by no means inevitable: there is a need to actively promote the adoption of these approaches and invest in skills and capacity”.

The ability to use technology to meet the long tail challenge and incrementally improve supply chain effectiveness starts with a clear statement of what the problem is, and what a good outcome looks like. Without a clear understanding of each task, each process and each problem to be solved, the benefits are likely to remain elusive.

Leading computer scientist and physicist Stephen Wolfram reflected on this when explaining how to reap the rewards of AI.

The challenge of making the most of technology is a human-centred problem; there is a need to work within your organisational limits, to articulate the problems that are known, and find the right solution before taking the next incremental step to improve the next business process.

In high-volume fast changing businesses, agile practices and fast decision making are critical. The primary task is in knowing precisely what is happening, and what the cost value and sale value is, as soon as possible, and as accurately as possible.

To deliver these changes, there is a need for very precise real-time inventory control and speed of information and actions. Whether in planning or in executing, the level of data has to be granular, down to the consignment and its pallets.

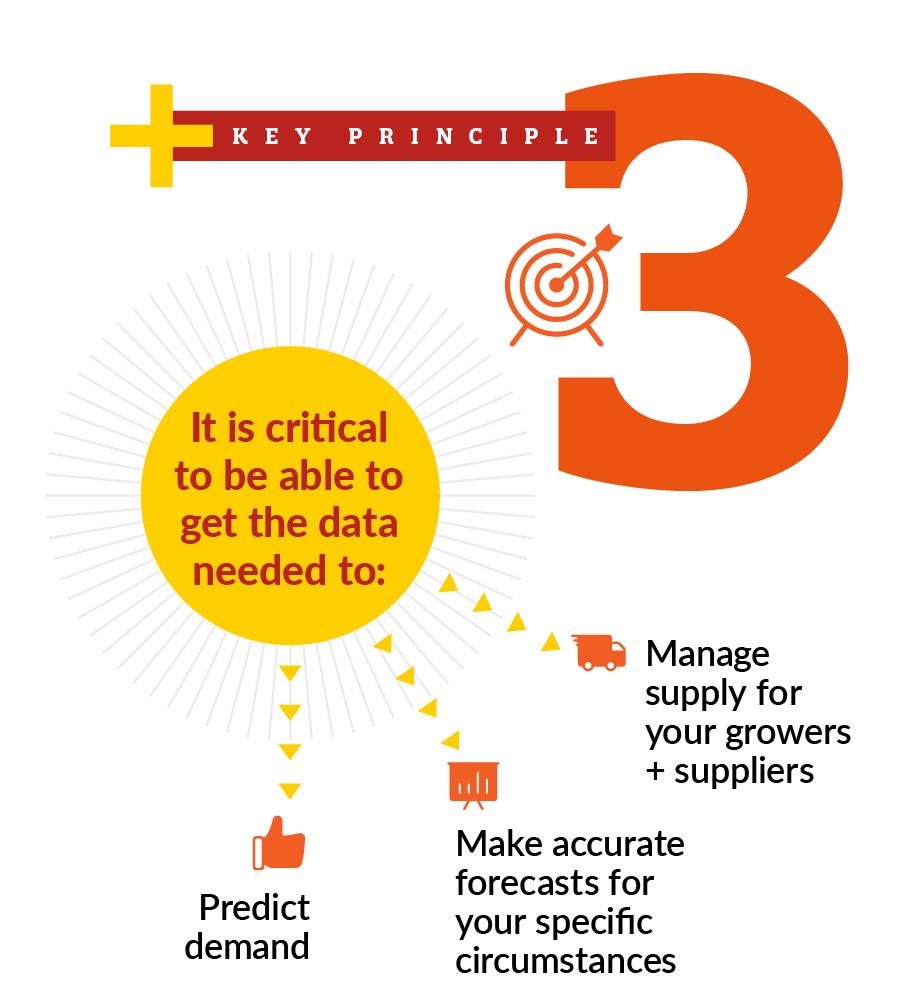

The ability to process big data on weather, growing conditions, transport and logistical factors is already delivering substantial benefits. The fundamental challenge is the sharing of this data so that it impacts throughout the supply chain.

The tasks that need to be performed have to be part of an integrated set of applications that can operate on the same database in near real-time without locking up data or introducing any lags into updating or retrieving data.

The path to automation and artificial intelligence starts with data and smart software. A completely digitised and intelligent supply chain requires fresh produce businesses to make a long standing commitment to high quality data and to enable automation throughout all business processes and tasks. These changes will enable fresh produce companies to implement software that is capable of intelligently managing their processes and tasks, and managing the risks and complexities inherent in the fresh produce supply chain.